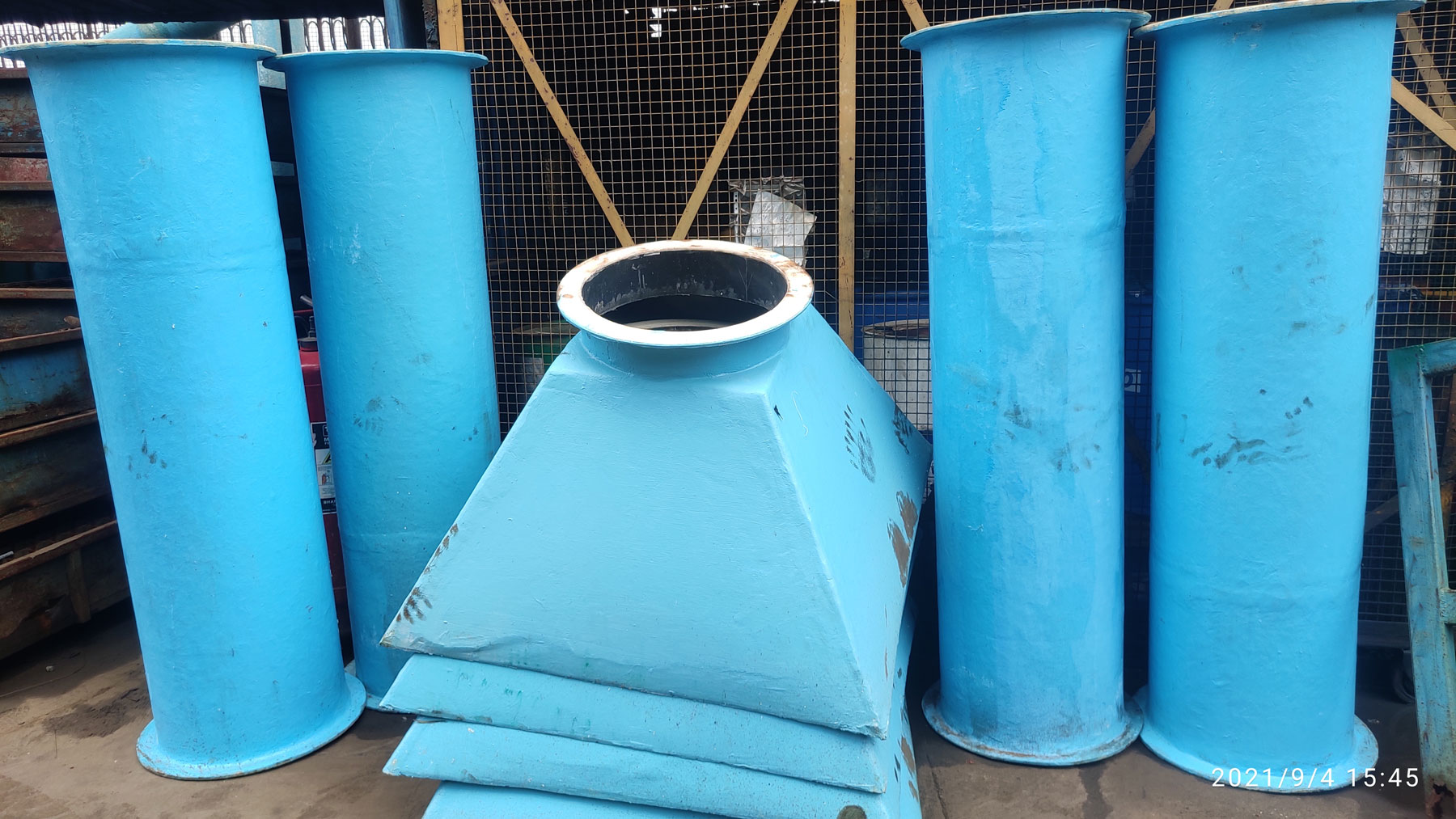

FRP Pipes & Fittings

Excel engineering manufactures frp and pp/frp pipes of various sizes and thickness as per client requirements.

This composite material is carefully manufactured using appropriate resin fiber glass reinforcements.

Advantages of frp pipes: –

- Corrosion Resistance:-Highly resistant to chemicals, acids, alkalis, and saltwater—ideal for corrosive environments.

- Lightweight:- Easier to handle, transport, and install compared to metal or concrete pipes.

- High Strength-to-Weight Ratio:- Despite being lightweight, FRP offers excellent mechanical strength.

- Long Service Life:- Resistant to wear and corrosion, resulting in lower maintenance and a lifespan of 30–50 years.

- Low Maintenance: Requires minimal upkeep due to its non-reactive and smooth inner surface.

- Smooth Inner Surface (Low Friction Loss):-Improves flow efficiency and reduces energy costs in fluid transport.

- Thermal and Electrical Insulation:-Non-conductive, making it safe in electrical environments and resistant to heat transfer.

- Customizable Design:- Can be easily moulded into various shapes and sizes for different industrial applications.

- Non-Magnetic:- Suitable for use in sensitive environments like radar or MRI areas.

- UV Resistant (With Additives):- Can be made UV resistant for outdoor use with appropriate coatings.

- Leak-Free Joints:- Modern jointing systems (like adhesive bonding or flanges) provide secure and leak-proof connections.

- Low Installation Cost:- Lower labour and equipment costs due to ease of handling and quicker installation.

- Environmentally Friendly:- Recyclable and longer-lasting, reducing the frequency of replacements and waste.

Comparison: FRP vs PVC vs HDPE vs Steel Pipes and Fittings

| Criteria | FRP (Fiberglass) | PVC (Polyvinyl Chloride) | HDPE (High-Density Polyethylene) | Steel (Carbon/Stainless) |

| 1. Corrosion Resistance | ✅ Excellent – chemically inert | ✅ Good – resistant to many chemicals | ✅ Excellent – ideal for corrosive soils | ❌ Poor – corrodes without coatings |

| 2. Strength | ✅ High strength-to-weight ratio | ❌ Moderate – brittle under impact | ✅ Good – flexible, not brittle | ✅ Very high |

| 3. Weight | ✅ Lightweight | ✅ Lightweight | ✅ Lightweight | ❌ Heavy |

| 4. Installation | ✅ Easy & fast | ✅ Easy, but joint integrity is critical | ✅ Easy with fusion welding | ❌ Labor-intensive & time-consuming |

| 5. Temperature Resistance | ✅ Moderate to High (depends on resin) | ❌ Low – softens above 60°C | ✅ Moderate (up to 80–100°C) | ✅ High (up to 400°C) |

| 6. Pressure Handling | ✅ Good | ❌ Limited | ✅ Good – depends on wall thickness | ✅ Excellent |

| 7. Flexibility | ❌ Rigid | ❌ Rigid | ✅ Very flexible | ❌ Rigid |

| 8. UV Resistance | ✅ With UV additives | ❌ Degrades under sunlight | ✅ With additives | ✅ With coating |

| 9. Life Span | ✅ 30–50+ years | ✅ 25–40 years | ✅ 40–50 years | ✅ 25–50+ years (if protected) |

| 10. Maintenance | ✅ Very low | ✅ Low | ✅ Low | ❌ High – prone to rust, scaling |

| 11. Cost (Initial) | ❌ Medium to High | ✅ Low | ✅ Medium | ❌ High |

| 12. Environmental Impact | ✅ Recyclable, fewer replacements | ❌ Less eco-friendly | ✅ Recyclable | ❌ High carbon footprint |

| 13. Jointing | ✅ Leak-proof options (adhesive, flanged) | ❌ Risk of leakage (solvent weld) | ✅ Strong fusion joints | ✅ Strong (welded/flanged) |

| 14. Abrasion Resistance | ✅ Good | ❌ Moderate | ✅ Good | ✅ Excellent |

| 15. Electrical Conductivity | ✅ Non-conductive | ✅ Non-conductive | ✅ Non-conductive | ❌ Conductive |

✅ When to Choose Each:

- FRP: Best for chemical plants, wastewater treatment, industrial corrosive fluids, and marine environments where corrosion resistance, long life, and strength are critical.

- PVC: Ideal for low-pressure, low-temperature applications like residential plumbing, irrigation, and drainage systems.

- HDPE: Suitable for underground piping, water mains, gas lines, and flexible fluid transport — offers excellent impact resistance and joint integrity.

- Steel: Chosen for high-pressure and high-temperature applications like steam lines, firefighting systems, and oil & gas where mechanical strength is vital.

Free to write our team anytime

Contact Us